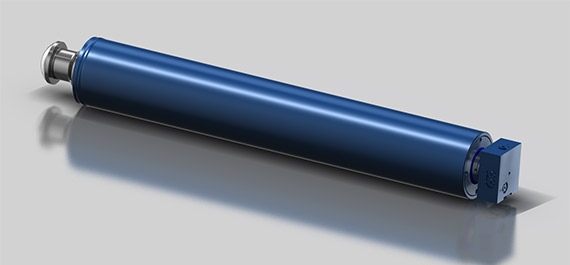

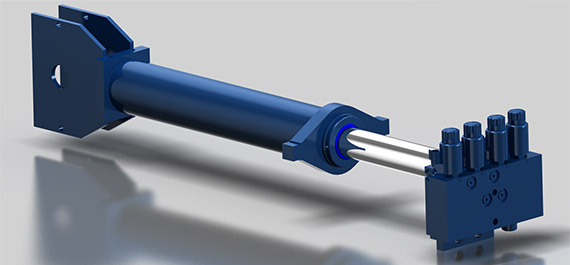

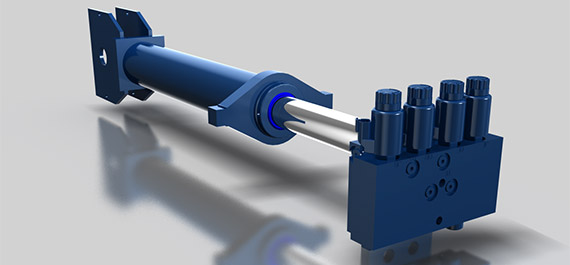

Texas Hydraulics’ EAS-i Actuator is a self-contained system, which controls cylinder motion to perform a programmed function or to respond to an input. The EAS-i Actuator can provide closed-loop feedback on pressure, temperature, cycles, angle, velocity and/ or position from the actuator to the on-board controller and can be customized to your system.

Applications: Material Handling, Utilities, Road Service, Oil & Gas, Defense, Transportation, Agriculture

Features

- On-Board Electronic Controller

- Input System Which Feeds into the Controller with Secondary Input Capability

- Hydraulic Cylinder Designed to Match Application Requirements

- Easily Programmable Logic

- Equipment Function Synchronization and Sequencing

- Work Envelope Control

- Speed/Acceleration Control (Electronic Cushion/Velocity Control)

- Position, Velocity, Temperature, Cycles and Pressure Feedback Devices

- Parallel/Series System Capability (Lift/Steer – Rotate/Tilt – Etc.)

- Hydraulic Integrated Circuit (HIC) Valve Manifold Utilizing Load Holding, Flow, Pressure, Proportional and Directional Control Cartridge Valves

- Links to the Various Data Transfer Lines in the Main Control System (J1939 and CANbus)

Optional Features

- Simplified Electro-Hydraulic Systems

- Fully Tested, Plug-and-Play Solution

- Control Solution Designed around Application and Desired Function

- Highly Flexible and Modular

- Easy Troubleshooting and Repair

- Increased Stiffness and Control due to Valve Proximity

- Provides Simple, Local Feedback

- Decreased Number of Leak Points

- Lower Heat Generation and Improved Efficiency through Optimized Pressure Drops

- Decreased Part Numbers and Less Inventory Control Required

- Allows for Improved Performance and Reliability in Various Environments